LED Display PCB Soldering

Drag soldering, production speed up to 700 pcs/hr, high operation stability, smooth and full solder joint, no flux splatter and no cold solder joint.

After being put on stream for a half year, OKATA PCB soldering machine has perfectly met the customer’s requirements, which helped them save the labor costs of 3 workers. The client has reordered a LED display PCB soldering machine and all soldering work are all conducted by OKATA soldering robots now.

-

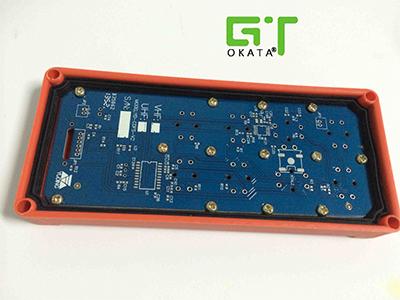

Product to be processed

-

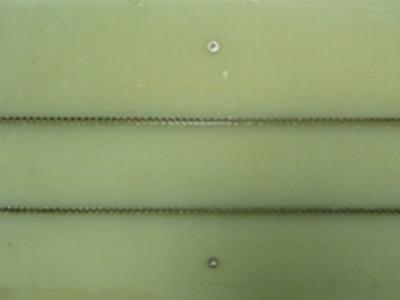

Already soldered product

Two LED products can be placed on each clamping fixture, which shares the bottom die with each other. The clamping fixture is easy to replace products and features high efficiency and excellent performance. (shown as the following picture)

OKATA auto soldering machine GT-HJ401DB

Automatic Welding/ Soldering Machine & Solutions