Case

Ipad Ipad Cable Soldering

Cable soldering requirements

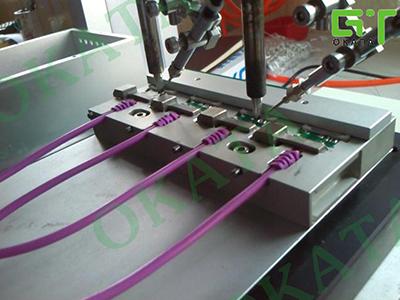

The product is shown as follows. The cable, plugin and circuit board should be welded together and there should be no missing solder joint or cold solder joint.

The high soldering quality of the IPAD cable needs to be ensured with defective rate lower than 1‰.

OKATA GT-HJ402DB automatic soldering solution

- Features

Table-top double head auto soldering machine. PLC control, precise operation, high stability. Double soldering head delivers higher production efficiency as twice as the single head soldering machine. - Clamping fixture

The custom-tailored clamping fixture is designed by our professional mechanical engineers according to customer’s requirements. The operator only needs to pick and take out the clamping fixtures which OKATA will provide two sets for replacement. - Operations

The soldering robot is fully automatic. The workers only need to put the cables on the clamping fixture of platform and press the start button, then the soldering robot will handle the products as designed programs. While the robot is working, the operator can prepare the next product in advance to speed up production pace.

Guangdong Okata Intelligent Technology Co.,Ltd. has been playing its part in the movement of automation development since our founding in 2005. Our concentration is on the R&D and production of high-precision automation equipment for unmanned production workshops. Our core products include automated soldering machines, automatic screw driving machines, and automatic dispensers. These pieces of advanced equipment are utilized by producers of electronics, electrical appliances, toys, communications equipment, cars, and other industries. We provide systematic automated solutions and comprehensive equipment that has made us a well-known enterprise in the industry.

Send an Inquiry

Automatic Welding/ Soldering Machine & Solutions