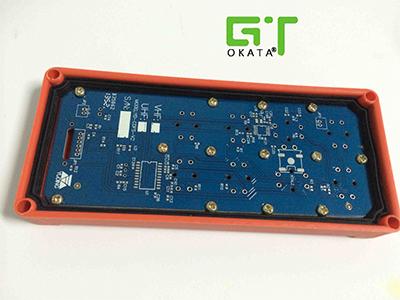

Instrumentation Soldering

In this case, four 400mm-stroke single welding gun automatic soldering machines were provided by OKATA to meet customer’s requirements of processing 4000 products every day. The production line used to have 8 workers and the utilization of the soldering equipment has reduced the number to 5, among of which are 4 operators responsible for putting clamping fixtures and 1 for quality inspection. OKATA helped our customers save labor cost of three workers. In order to maintain the operation stability of soldering system, the quality of all components used are strictly controlled. And eventually the long-time stable running of this instrumentation soldering equipment has proved our production strengths and earned customer’s board trust.

This PLC control soldering machine can precisely solder products with high precision in accordance with the preset coordinates and the speed reaches to 1.2 seconds per point. The 400mm stroke soldering machine is widely used. It can perform drag welding and the simultaneous work of product processing and loading is available. The soldering system also allows to storage many soldering plans, ideal for a variety of products.

Automatic Welding/ Soldering Machine & Solutions